NK-MES

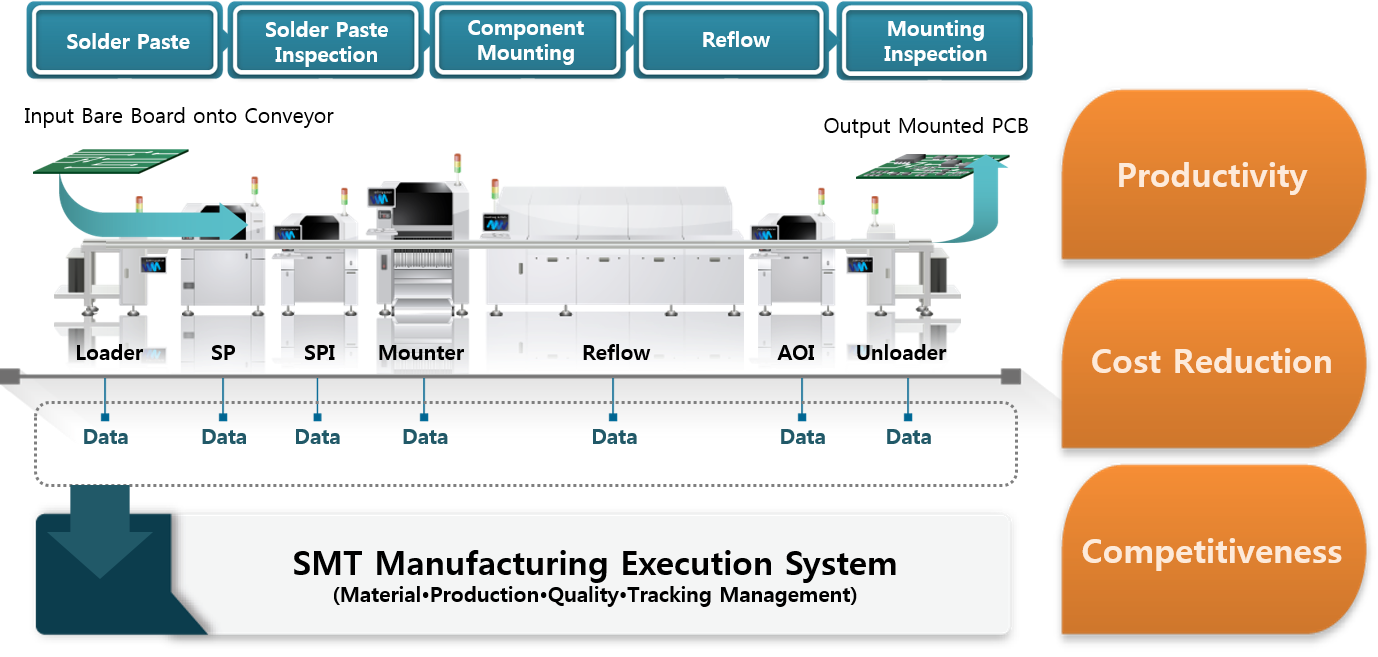

NK-MES is the Manufacture Execution System for SMT Line which has developed with High Technology and overall knowhow of Namkang Hi-tech experience for SMT-MES application S/W over 20 years. With Modular System, you can reduce the time and cost for system construction.

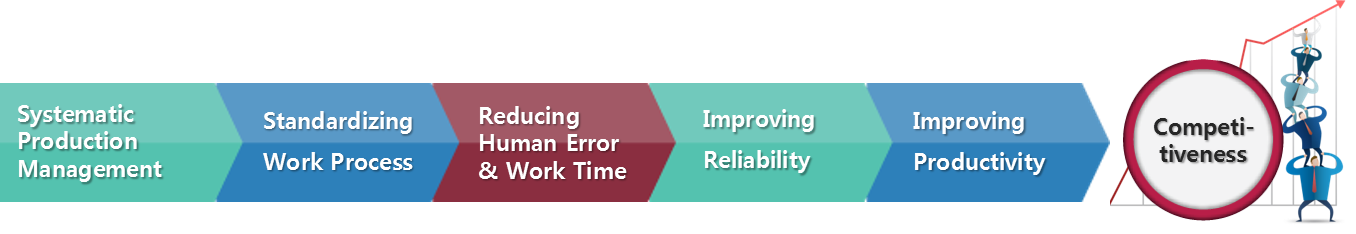

NK-MES is possible to manage integrated the real-time data from various production data of heterogeneous SMT machines. It can prevent human error from the complex manual task and dispersed data by the management of production information with real-time accurate data from the SMT Equipment for improving data reliability and working environment, reducing working time, and enhancing competitiveness.

Effectiveness of NK-MES

1. Prevention of Human Error in Material Exchange process by RESPS.

2. Improvement the effectiveness of Material managing.

3. Convenience of Product managing with systematic production management.

4. Improvement of Production Reliability with the work process standardization.

5. Real- time Monitoring of Production information.

6. Securing the competitiveness by effective quality managing.

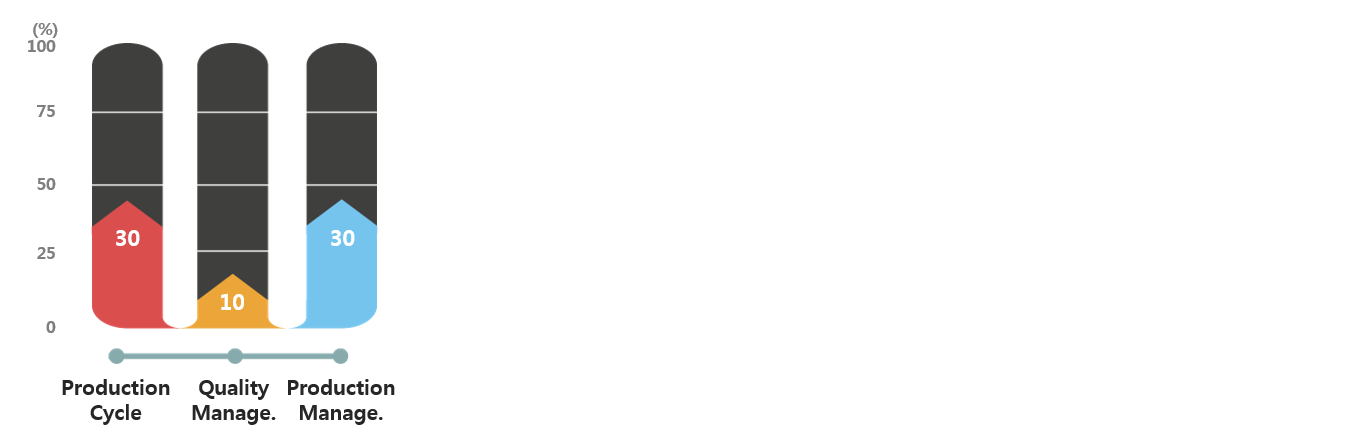

Reducing work time with NK-MES operation

[ Production cycle]

Production cycle time has reduced over 30% by removing unnecessary process to avoid repetitive work with standardizing the work process and traceability.

[ Quality Management ]

Reliability of Quality management has increased over 10% by the management of NG information and tracking data.

[ Production Management ]

Production managing effectiveness has improved over 30% by automatic interfacing with data from each SMT Process Equipment.